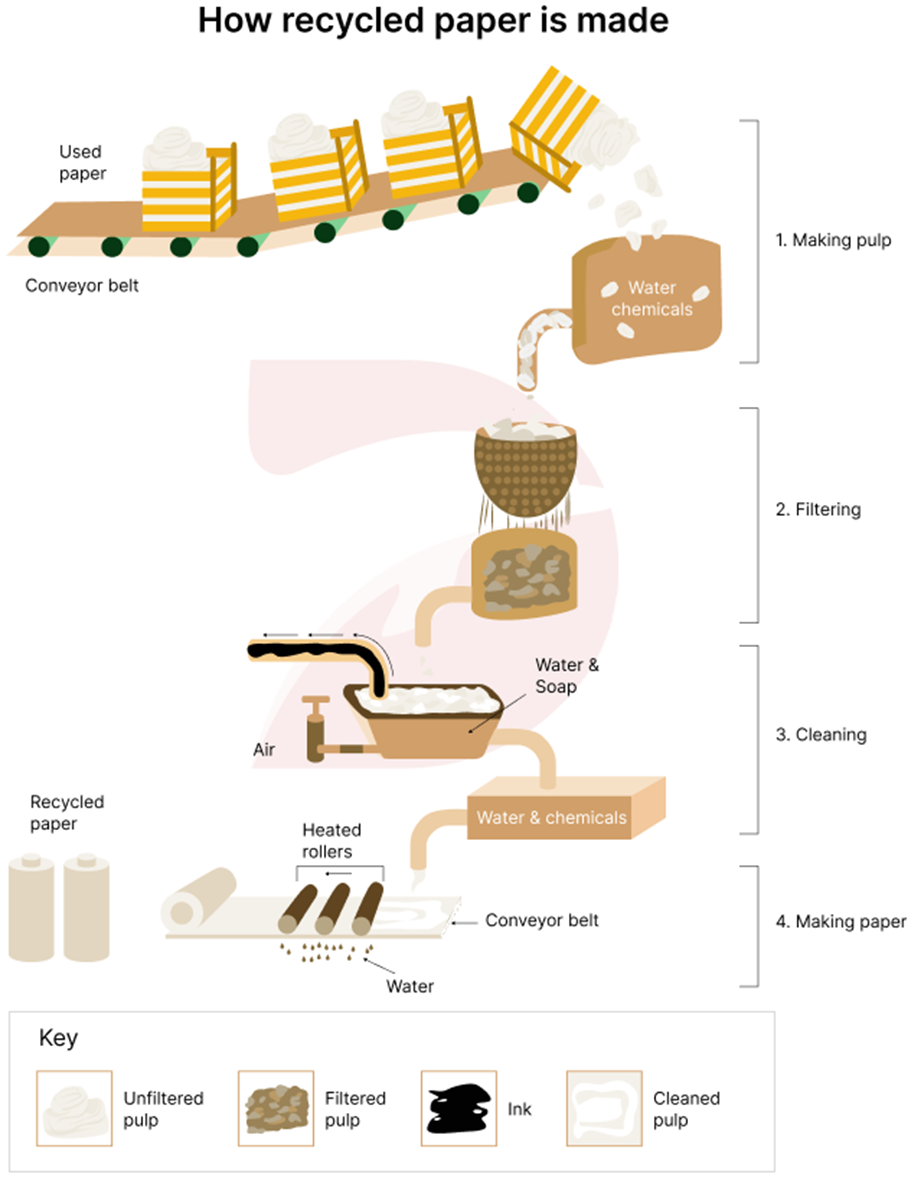

The diagram illustrates how recycled paper is made.

Summarise the information by selecting and reporting the main features, and make comparisons where relevant. Write at least 150 words.

The diagram illustrates how recycled paper is made.

Summarise the information by selecting and reporting the main features, and make comparisons where relevant. Write at least 150 words.

Câu hỏi trong đề: 2000 câu trắc nghiệm tổng hợp Tiếng Anh 2025 có đáp án !!

Quảng cáo

Trả lời:

Sample 1:

The given diagram presents the stages involved in the process of recycling paper.

Overall, this process includes four main phases, beginning with the making of pulp and ending in the production of recycled paper.

In the first step of the recycling process, used paper is placed on a conveyor belt which moves it into a mixture of water and chemical agents, where the paper is broken down into individual fibers, forming a slurry-like pulp as a result. Next, the slurry undergoes a filtration process to assist in the removal of impurities.

This is followed by a stage of thorough cleaning, in which water, soap, and air are used to wash the pulp and eliminate ink residues before more water and chemicals are added to enhance the removal process. In the fourth stage, the cleaned pulp is poured onto another conveyor belt, which carries the pulp through a drying process involving the use of heated rollers to remove the water. Finally, the dried paper is then wounded into rolls of recycled paper, ready for use or distribution.

Sample 2:

The diagram illustrates the process for manufacturing recycled paper.

Overall, this is a mechanical process comprising four main stages: pulp creation, filtration, cleansing, and paper production.

The first stage starts with the collection of used paper, which is placed onto a conveyor belt. The paper is then transferred into a pulping machine, where it is mixed with water and chemicals to break it down into a slurry.

During the second stage, the pulpy mixture is sieved, which results in a more homogeneous and cleaner pulp. The third stage is the cleaning phase, where the pulp is thoroughly washed with water and soap. Additionally, the air is fed into the pulp so that smaller impurities, such as ink particles, can be removed. The pulp thereafter undergoes another round of chemical and water treatment.

Once the cleaning step has been completed, the pulp is laid out on a conveyor belt and passed through heated rollers, which press and dry the pulp into paper. The paper is subsequently rolled up, resulting in rolls of recycled paper ready for distribution and use.

Sample 3:

The drawing illustrates the step-by-step process of recycling paper.

Overall, it can be seen that this procedure consists of eight stages, divided into four main phases. This begins with the collection of used paper and ends with the attainment of recycled paper.

During the making pulp and filtering processes, used paper is first gathered in containers, which are put on a conveyor belt. Once reaching the end of the belt, the paper is deposited into a tank containing water and chemicals to be broken down into a slurry. This is followed by the slurry being filtered into another container.

In the cleaning and making stages, the filtered pulp is mixed with water and soap, and air is introduced in order to remove ink. Following this, the deinked pulp is transferred to a tub with water and chemicals, which then releases the clean pulp onto another conveyor belt. Heated rollers are subsequently introduced to dry the pulp, resulting in recycled paper, while excess water is collected separately.

Sample 4:

The diagram details the process of producing recycled paper. Overall, the process comprises four primary stages, commencing with a pulping phase, followed by filtration and cleansing stages, and culminating with the final recycled paper being rolled.

Regarding the pulp production and filtration stages, the boxes containing used paper are placed on a conveyor belt and transferred to a tank filled with water and chemicals. Subsequently, the paper is converted into pulp for additional processing. Next, the pulp is transferred to a receptacle equipped with perforations to eliminate impurities and then poured into a container.

Concerning the cleaning and papermaking stages, the pulp is put into a large floatation tank filled with water and soap. Air is pumped into the tank to help remove ink, enhancing the purity and whiteness of the pulp. Once the pulp has been de-inked, it is moved to another tank with water and chemicals for a final cleaning. In the next step, the pulp passes through heated rollers, during which water is extracted. Finally, long rolls of recycled paper are produced.

Sample 5:

The given diagram delineates the process of recycling used paper.

Overall, it can be clearly seen that there are 4 main stages in the process, commencing with the making of pulp from used paper and culminating with recycled paper as the final product.

In the first stage of creating the pulp, used paper is transported by a conveyor belt before being treated with a liquid consisting of water and chemicals in a tank to create unpurified pulp. And then in the filtering phase, water and soap are added into a tank to remove the ink from the raw pulp, with the assistance of the air pump.

Next, clean pulp, which is the outcome of the previous cleaning step, is moved through a line to the heated rollers. Here, the clean pulp is rolled flat to create sheets of new paper. Moreover, before the final product is made, in the process of flat-rolling and with the involvement of heat, the previously added water is completely removed.

Sample 6:

The picture depicts the step-by-step process of creating recycled paper.

Overall, the process consists of four key stages, which commences with the production and then filtration of raw pulp, proceeds to the deinking process, and culminates in the production of rolls of recycled paper crafted from purified pulp.

The initial step involves producing unprocessed pulp, which initiates with the pulp placement on a conveyor belt, followed by its descent into a water and chemical mixture. Subsequently, the blend is funneled into a bucket, extracting the liquid and releasing the filtered pulp into another container.

In the next stage, the filtered pulp is immersed in a bucket containing water, soap, and introduced air, causing the ink in the pulp to evaporate. Following this, the deinked pulp flows into another container to ultimately yield clean pulp. This is subjected to grinding by heated rollers on a conveyor belt to completely remove water, resulting in the production of rolls of recycled paper.

Sample 7:

The given illustration outlines the step-by-step process of recycled paper production.

Overall, the production line involves four main phases, beginning with the reception of wastepaper, followed by the subsequent filtration of raw pulp and the de-inking stage prior to the production of recycled paper.

First, once being delivered to the manufacturing plant, the collected wastepaper will enter the pulping stage on a conveyor belt. Here, it is submerged in a liquid which is a combination of water and chemicals to be converted into pulp with ink and other impurities. Therefore, the mixture is transferred to a perforated vat for the impurities to be filtered out.

The next step is when the ink is removed by pouring the filtered pulp into another vat filled with water and soap, under the effect of air pumped into it. Once this step completes, the ink exits through a separate tube, while the resultant clean pulp is channeled through another tube into a container where it is rolled into recycled paper by a series of heated rollers on a conveyor belt, ensuring the water within the paper is thoroughly expelled.

Sample 8:

The diagram illustrates the process of making recycled paper from used paper. The process involves four main stages: making pulp, filtering, cleaning, and making paper.

In the first stage, used paper is placed on a conveyor belt that moves it into a pulping machine. Here, water and chemicals are added to break down the paper into unfiltered pulp.

The second stage is filtering, where the unfiltered pulp is passed through a mesh to remove large impurities. This results in the filtered pulp, which is then ready for the cleaning stage.

During the third stage, the filtered pulp is mixed with water and soap, which helps to remove ink and other small contaminants. Air is also introduced to further clean the pulp. The cleaned pulp is then passed through another filtration process to ensure all impurities are removed.

Sample 9:

The diagram demonstrates the procedure for manufacturing recycled paper from used one.

The whole process involves seven steps which can be organized into three main stages. This includes collecting used paper, filtering it and processing the materials into the finished product.

Initially, unprocessed pulp is filtered by being placed on a conveyor belt and then submerged in water and chemical mixture. The blend is then poured into a straining bucket, separating the liquid and leaving filtered pulp.

Next, the filtered pulp undergoes a cleaning process, where it is submerged in a mixture of water, soap, and air. This process causes the ink in the pulp to evaporate, resulting in deinked pulp. The deinked pulp is then mixed with water and other chemicals in another vessel, eventually yielding clean pulp. Finally, the clean pulp is passed through heated rollers on a conveyor belt, where it is ground and transformed into rolls of recycled paper.

Sample 10:

The diagram illustrates the stages involved in the recycling of used paper.

Overall, the process encompasses a series of distinct phases, namely pulping, filtering, cleaning, and paper making. Specifically, it starts with a conveyor belting moving used paper and the final stage is when the paper is fully recycled.

Initially, used paper is conveyed on a belt to a vat, where it is mixed with water and chemicals to break it down into fibers, commonly referred to as unfiltered pulp. Following this, the substance is subjected to a filtration process to eliminate larger particles. The next phase is deinking, which involves the filtered pulp being treated with a mixture of water and soap to remove any remaining impurities. During this stage, an air pump is introduced to create bubbles, causing the ink to rise to the surface, which is then removed through a dedicated pipe. This step is essential for ensuring that the final product is free from any residual printing substances.

Once the pulp is cleaned, it is formed into rolls of recycled paper through the utilization of heated rollers, which expels any remaining water and facilitates the solidification of the paper into its final form.

Sample 11:

The provided diagram illustrates the process involved in recycling paper.

Overall, it is clear that the recycling of paper involves a comprehensive four-stage procedure, from the first treatment of wastepaper to the final production of usable recycled paper.

The initial phase commences when wastepaper is placed onto a conveyor belt. After that, it is transported to a container where it is mixed with water and chemicals, which facilitate the breakdown of the paper into a mushy substance called unfiltered pulp. This mixture then undergoes a thorough cleaning stage, where air, water and soap are introduced to eliminate impurities. Following that, the pulp goes through an additional bleaching step, which removes any remaining ink, resulting in a batch of clean pulp. As the final step, this purified pulp is passed through a heated roller, which dries the pulp and begins forming the recycled paper, ready for a new life in various applications.

Sample 12:

The diagram illustrates the process of industrially recycling used paper into new usable paper rolls.

Overall, this process is divided into four clear stages, beginning with turning used paper into pulp and ending with rolling clean pulp into new paper.

During the first stage, collected wastepaper is delivered on a conveyor belt and consequently soaked in a mixture of water and chemicals, turning the used paper into pulp in preparation for the next stage. The pulp mixture is then pushed through a filter in the second stage before the ink removal process.

Next, in the third stage, the filtered pulp continues to be soaked in water while an air pump is utilised to separate the ink from the pulp. Afterwards, the resulting clean pulp is run through heated rollers, during which, any excess water is drawn out. The outcome of this final stage is fresh rolls of recycled paper.

Sample 13:

The process graph illustrates the stages involved in the making of recycled paper.

Overall, it can be seen that used paper undergoes four main stages. The process begins with the production of pulp and ends with the rolling of clean pulp to make recycled paper.

In detail, in the first stage of the process, used paper is dropped into a tank containing water and chemicals, with the help of conveyor belt. The pulp is then filtered by putting into a barrel with holes. This process separates the impurities from the pulp, leaving them behind inside the barrel.

Following this is the cleaning stage, in which filtered pulp is washed with water and soap in a container. Air is also passed into the container with the help of an air pump, which is attached to the container. The ink gets removed in this stage. In the final stage, the clean pulp without ink is rolled with the help of the heated roller. The wastewater is removed and thus, recycled paper rolls are obtained.

Sample 14:

The diagram meticulously delineates the systematic process involved in recycling paper.

The process encompasses four principal stages: beginning with the creation of pulp and concluding with the production of recycled paper, each step intricately linked to form a continuous sequence.

Initiating this cycle, used paper is gathered and deposited on a conveyor belt, conveying it to a pulping machine. Here, amidst a blend of water and chemicals, the paper is disintegrated into a slurry. This slurry is then subjected to a filtration process, whereby the mixture is sieved to yield a cleaner, more uniform pulp, effectively preparing it for the subsequent cleaning stage.

In the third stage, the filtered pulp is rigorously cleansed using water and soap, with air being infused to facilitate the removal of fine impurities, including ink. This results in a clean pulp, which is then evenly distributed on another conveyor belt. Passing through heated rollers, the pulp is pressed and dried, finally emerging as sheets of paper. These sheets are rolled up, signifying the end of the recycling process and producing rolls of recycled paper ready for use.

Sample 15:

The linear manufacture of recycled paper is illustrated in the given diagram.

Overall, the process comprises various stages, commencing with the production of pulp, followed bystages of industrial parts cleaning and culminating in the completion of recycled paper.

In greater detail, the initial phase of making pulp is to transport used paper through a conveyor belt to a processed mixture of water and chemicals, where it is broken down and shredded into small pieces to create unfiltered pulp slurry. Having undergone a filtration stage to get rid of residues and impurities, the materials are then transmitted to a more complex process thereafter.

As far as the remaining steps are concerned, the filtered pulp is cleaned entirely by water, soap and air to remove ink and other contaminants before being added to another mixture of water and chemicals. Afterwards, the soaked materials are poured down into a conveyor belt, passing through heated rollers to evaporate the moisture. The manufacture ends with the wounding of dry paper sheets into recycled paper, ready to be consumed.

Sample 16:

The diagram details how recycled paper is made. Looking from an overall perspective, it is readily apparent that the process involves three main stages beginning with initial collection and transportation, followed by cleaning and processing, and lastly the rolling of the final product. The process is entirely man- made.

In order to produce recycled paper, used paper is first sourced and transported by conveyor belt to a processing plant. The used paper is then made into unfiltered pulp by using water and various chemicals. The pulp must then be filtered with water being removed.

After filtering is complete, the filtered paper pulp is sent by a tube to a container with water and soap to be further cleaned. The air is pumped into the container and the ink is removed. There is then additional cleaning with water and chemicals before the final rolling stages commence. To create usable recycled paper rolls, the cleaned and filtered pulp is placed on a conveyor belt where heated rollers flatten the paper and remove excess water.

Hot: 1000+ Đề thi giữa kì 2 file word cấu trúc mới 2026 Toán, Văn, Anh... lớp 1-12 (chỉ từ 60k). Tải ngay

- Sổ tay Lịch Sử 12 (chương trình mới) ( 18.000₫ )

- 250+ Công thức giải nhanh môn Toán 12 (chương trình mới) ( 18.000₫ )

- Sổ tay lớp 12 các môn Toán, Lí, Hóa, Văn, Sử, Địa, KTPL (chương trình mới) ( 36.000₫ )

- Tuyển tập 30 đề thi đánh giá năng lực Đại học Quốc gia Hà Nội, TP Hồ Chí Minh (2 cuốn) ( 150.000₫ )

CÂU HỎI HOT CÙNG CHỦ ĐỀ

Lời giải

Sample 1:

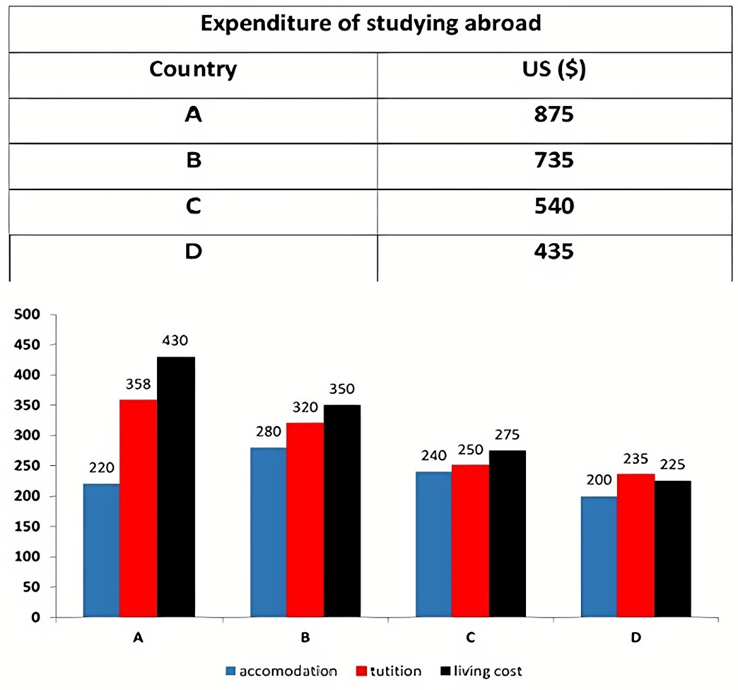

The bar graph illustrates the overseas students' spending on accommodation, tuition, and living expenses, while the table depicts information about the average weekly expenses by international students in four countries: A, B, C, and D.

Overall, foreign students need to spend the highest in country A and the lowest in D. In nearly every nation, the international students’ weekly average living expenses are the greatest, while their housing cost registers the lowest.

The costliest country for studying is A, with a weekly average expense of 875 dollars. This is followed by B, C, and D, which have weekly expenses of 735, 540, and 435 dollars, respectively. However, foreign students always pay the least for accommodation, which incurs on average weekly 220, 280, 240, and 200 dollars in the nations A, B, C, and D, respectively.

On the other hand, living expenditures account for the highest portion of average weekly costs for international students in countries A, B, and C, with 430, 350, and 275 dollars, correspondingly. Tuition fees in the same countries (A, B and C) come in second with the weekly averages of 358, 320, and 250 dollars in order. However, D is the only nation where education accounts for the highest average spending area, coming in at USD 235, followed by the cost of living (USD 225) and housing (USD 200).

Sample 2:

The table illustrates information regarding the weekly spendings by overseas students in four countries, A, B, C and D, while the bar graph depicts the students’ expenditure on the sectors, housing, education fees and living expenses.

Overall, the cost of studying abroad is the highest in country A and the lowest in D. Apart from country D, living costs account for the most part of the weekly spendings in all countries, while accommodation registers the least.

Regarding the total cost of studying, A is the most expensive country with weekly average 875 dollars, followed by B, C and D with 735, 540 and 435 dollars, respectively. On the other hand, the overseas students always spend the least on accommodation, which are on average weekly 220, 280, 240 and 200 dollars in the corresponding countries A, B, C and D.

Considering the living cost, it takes the largest share of foreign students’ average weekly expenses in countries A, B, and C with 430, 350 and 275 dollars, respectively, while tuition fees in the same countries hold the second place with weekly average 358, 320 and 250 dollars, sequentially. However, D is the only country where tuition fee occupies the highest expenditure with average weekly 235 dollars, followed by living cost (USD 225) and accommodation (USD 200.)

Sample 3:

The table and bar graph depict information regarding the weekly spendings by overseas students in countries A, B C and D.

Overall, there are three elements, housing, school fees and living costs that contribute to the total weekly spendings. The total expenditure in country A is the highest while it is the lowest in country D. Living costs account for the most part of the weekly spendings in all countries except D.

The total mean weekly cost for pupils to study in country A is US$875, next by country B at US$735, and then by country C at US$540, and finally by country D at US$435. The living costs are always the biggest component of the expenditure except for country D, with about US$10 less than the major spending which is the school fees.

Accommodation accounts for the least among all spendings in all countries. The most expensive housing is found in country B, at US$280, and the cheapest in country D at US$200. The middle range can be seen in country A at US$220 and country C at US$240, respectively. Costs of the tuition fee range between US$ 358 and US$235 in country A and D, in order.

Lời giải

Sample 1:

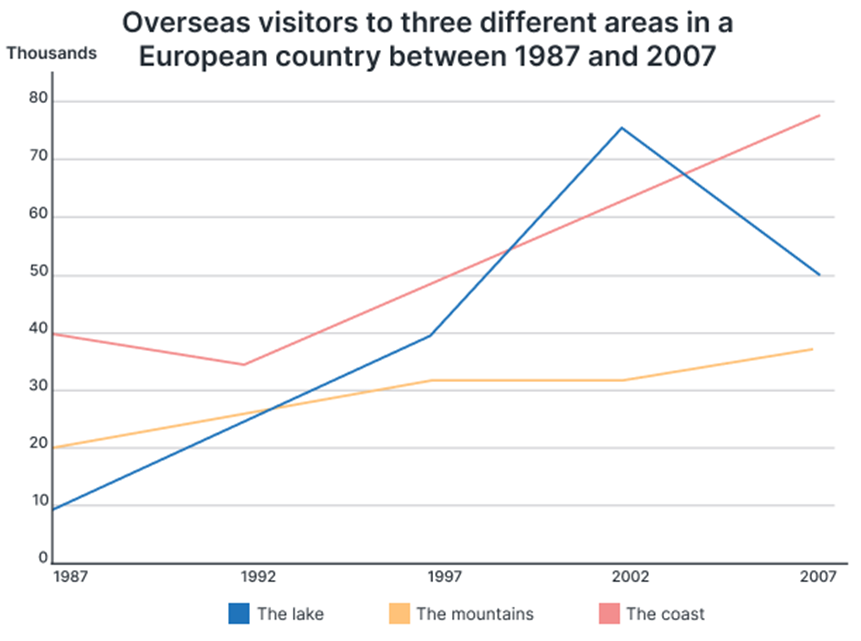

The chart illustrates a comparison of the three kinds of foreign tourist visits to a certain European nation during a twenty-year period, beginning in 1987 and ending in 2007.

Overall, the majority of survey years showed that most foreign visitors flocked to coastal locations, while mountainous places received the fewest. Furthermore, the number of visitors visiting all three locations rose throughout this time frame.

Over 40,000 tourists from outside of this European nation visited its shore in 1987. Its number plummeted to roughly 35,000 in 1992 but has steadily increased since then, peaking at over 75,000 in 2007. Meanwhile, the annual number of international visitors to the mountains ranged from 20,000 to 30,000 in the first half of the decade and then jumped to 35,000 in 2007.

For the first fifteen years, the number of international visitors to this country's lakes steadily increased, reaching a high of 75,000 in 2002. In the following years, however, this number dropped dramatically, reaching 50,000 in 2007.

Sample 2:

The chart presents a comparative analysis of three categories of foreign tourist visits to a specific European nation from 1987 to 2007.

In general, there was a consistent increase in the number of tourists across all three locations throughout the specified period. Coastal areas witnessed the highest influx of foreign tourists in almost all the periods.

The year 1987 marked the arrival of over 40,000 foreign tourists to the nation’s coastal regions. However, this figure experienced a decline, dropping to approximately 35,000 visitors by 1992. The numbers then surged significantly, peaking at over 75,000 visitors by 2007. Conversely, visits to mountainous locations started at the second highest level of 20,000, progressing to over 30,000 in 1997. Thereafter, this figure stayed unaltered towards 2002 before a modest increment to about 38,000 in 2007.

The volume of international tourists visiting the country’s lakes saw consistent growth over the initial fifteen years, reaching a pinnacle of 75,000 visitors in 2002. Subsequently, there was a substantial decline in visitation, plummeting to 50,000 by the year 2007.

Sample 3:

The graph illustrates the number of tourists to three distinct regions in a European country, spanning from 1987 to 2007. Overall, the places have experienced an increased tourist attraction from the past two decades.

Initially, the coast, with around 40,000 visitors, was known to be the most popular region among the three. On the contrary, the lakes were the least liked, only comprising around 10,000 visitors. It is also notable that both the coast and the lakes had the same number of maximum visitors in this period, which was around 75,000.

By 2007, the coast had become the most popular tourist destination, having visited by almost 75,000 visitors. Although the lakes too saw a steep rise initially, the visitors started to decline, gaining the maximum attraction of approximately 75,000 tourists in 2002. By 2007, it had declined to 40,000 visitors. The mountains surprisingly did not experience any great inclination. They only had around 15,000 more visitors since 1987.

Sample 4:

The given graph illustrates the number of overseas travellers who visited three different attractions in a European country from 1987 to 2007. It is noticeable that the number of tourists visiting all the areas witnessed an upward trend over the given period.

In 1987, the coast attracted the most overseas visitors, with 40 thousand while the converse held true for the lakes, with only 10 thousand. Over the next two decades, the number of overseas tourists opting for the lakes rose gradually to approximately 35 thousand. Similarly, there was a dramatic jump in the number of visitors to the lakes to about 75 thousand, followed by a drop to 50 thousand in 2007.

At the beginning of the period, 20 thousand tourists from other countries visited the mountains. The mentioned attractions welcomed 30 thousand visitors in 1997 and the figure remained relatively stable until 2002. At the end of the period, the number of tourists to the mountains reached the highest point of 35 thousand.

Sample 5:

The given line graph depicts information about how many foreigners visited three separate regions in a European nation, during the span of a 20-year period from 1987 to 2007.

Overall, the most notable detail is that those three regions all attracted an increasing number of foreigners. In addition, the lakes’ tourist figures witnessed the most dramatic change among those given.

In more detail, at approximately 10,000 visitors in 1987, the quantity of foreign travelers who were attracted to the lakes gradually rose to around 50,000 in 2000, before peaking at approximately 75,000 tourists in 2002, This figure then dropped back down to approximately 50,000 people in 2007.

With regards to tourist numbers in coastal and mountainous areas, the overall figures increased, however mountainous areas remained the least attractive travel option out of the three. In 1987, the number of those who chose the coast as a travel destination stood at 40,000, compared to only 20,000 travelers who went to the mountains. In the next 14 years, the coast witnessed a slight decrease in the quantity of visitors by a few thousand, which was followed by a significant climb to around 60,000 people, whereas the number of those visiting mountainous areas went up remarkably to 30,000 in 2001.

In the final 6 years, while the quantity of overseas tourists going to the coast rose moderately to above 70,000, there was a slight climb in those who paid a visit to the mountains to about 35,000.

Sample 6:

The line chart details statistics about foreign travellers to three types of tourist destinations in an unspecified nation in Europe from 1987 to 2007. Overall, all categories witnessed an upswing with the most significant growth being seen in the number of tourists to the lakeside areas.

The coastal region welcomed the highest level of alien sightseers in the first year, at 40,000. Despite dipping to about 35,000 five years later, it recovered rapidly and consistently to approximately 76,000 in the final year.

Regarding the visitors to the mountainous attractions, this figure rose moderately from 20,000 in 1987 to 30,000 in 1997. Subsequently, it documented a period of stability until 2002, followed by a rise of nearly 7,000 by the end.

Finally, starting at the lowest result of 10,000 in the beginning, the number of overseas tourists to the lakes surged to 40,000 by 1997. In the next five years, it increased more sharply to a peak of just over 75,000 which surpassed the coast, before dropping quickly back to second position with 50,000 by 2007.

Sample 7:

The given outline is the number of people who have gone to the distinctive three places (the coast, the mountains, and the lakes) in the European nation from 1987 to 2000. Looking at the by-and-large structure it is quickly clear that the number of worldwide guests to the coast has diminished over the past five years. In spite of the first moo numbers, there has been a sharp increment in the number of guests to the lake by the conclusion, whereas those going to the mountains have expanded slowly.

After dissecting the chart, it can be seen that in 1987, 40% of worldwide people went by the coast which declined to around 35% in 1992. After that, the esteem expanded to roughly 75% in 2007. While, in 1987, 20% of universal people went to see the mountains which expanded consistently to around almost 33% in 2007.

In 1987, the rate of outside guests was 10%, expanding to 40% by 1997. This figure rose to 72% in 2002, sometime recently dropping to 50% in 2007. The coast had the most elevated guest numbers among the three zones. In the interim, both the coast and the mountains experienced development in their guest tallies.

Sample 8:

The line chart outlines the number of universal sightseers gone by the diverse three places in a European nation from 1887 to 2007. The unit is measured in thousands. By and large, it can be apparent that an expansive lion's share of guests went to Europe in 2002 and 2007, and a few thousand individuals in 1987. A look at the chart reveals that more at that point 70 thousand people went by the lakes in 2002, and the same number of individuals went to the mountains in 2007. Within the same year, a decrease was observed in the number of guests who went to lakes as it was 50 thousand. In 1987, as it was, 40 thousand individuals visited the coastal regions, and after that sudden expanded drift watched from 1992 to 2007.

For the mountain ranges, 20 thousand individuals went in 1987, and exceptionally few increases were observed over a period of time. Around 35 thousand sightseers went by the mountains in 2007.

Lời giải

Bạn cần đăng ký gói VIP ( giá chỉ từ 199K ) để làm bài, xem đáp án và lời giải chi tiết không giới hạn.

Lời giải

Bạn cần đăng ký gói VIP ( giá chỉ từ 199K ) để làm bài, xem đáp án và lời giải chi tiết không giới hạn.

Lời giải

Bạn cần đăng ký gói VIP ( giá chỉ từ 199K ) để làm bài, xem đáp án và lời giải chi tiết không giới hạn.

Lời giải

Bạn cần đăng ký gói VIP ( giá chỉ từ 199K ) để làm bài, xem đáp án và lời giải chi tiết không giới hạn.

Lời giải

Bạn cần đăng ký gói VIP ( giá chỉ từ 199K ) để làm bài, xem đáp án và lời giải chi tiết không giới hạn.